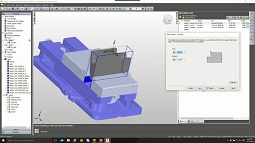

Automated CNC programming

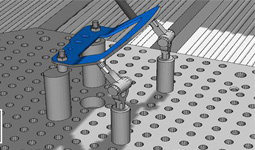

Program parts faster

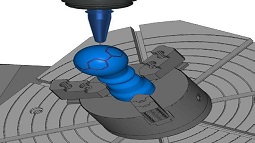

Use feature recognition to scan, identify, and create machinable features from your design

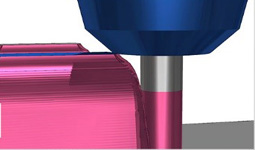

Built-in intelligence

FeatureCAM can help select your tools, stepover, stepdown, and more, providing programming

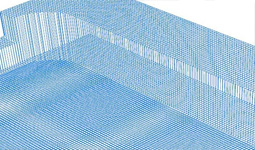

Programming control

Standardize and produce the results you want with libraries, configurations, and attributes